|

Tie Down Straps

Tie down straps

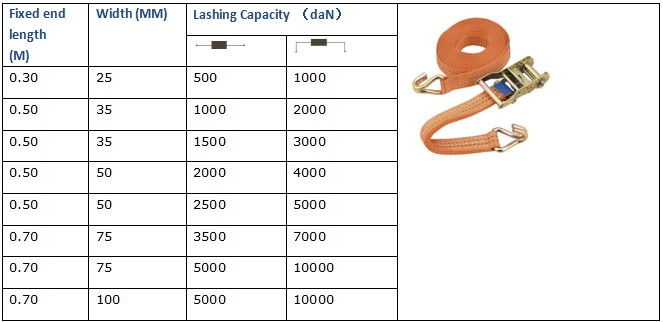

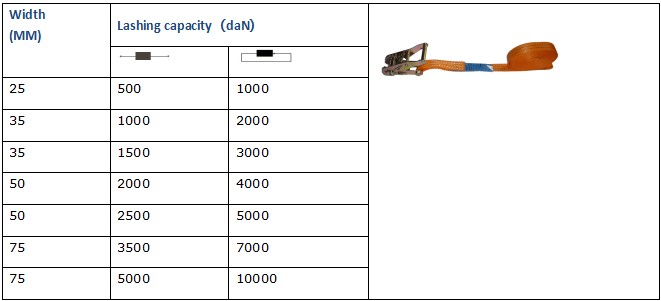

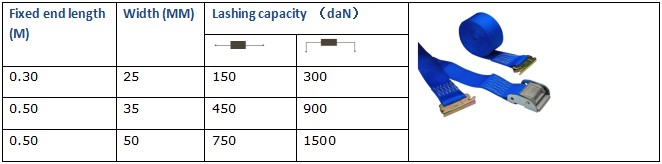

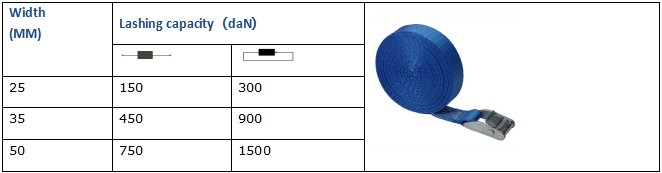

Features: 1. The black lines on sewn webbing show the minimum breaking force. If required, no showing the lines is available; 2. The end fittings by heat treatment are tight and safe on using. There are abundant items of fittings for option. It is convenient to handle. 3. The colors various, meanwhile, the colors as per requirement available. If required, PU coated or protective sleeve optional and applied to the straps. The imprint on webbing optional; 4. At 1 LC, their elongation not more than 7%; 5. They are of low capacity in water absorbing for the component of sewn webbing made of polyester material. Moreover, the straps are resistant to abrasion and get damaged from alkali easily, but resist the mineral acid. For the straps with polyester sewn webbing, their working temperature is -40 to 120℃(-40 to 248℉). Technical parameters: Material: 100% polyester or polypropylene. Performed standard:EN12195-2 Safety factor: 2 :1 Lashing capacity (LC):400 to 5000daN Width: 25 to 100MM Color: popular color, such as blue, orange, black, red, yellow, and gray, etc. Length: 1 to 16M or as required Ratchet tie down strap (Two part)  Ratchet tie down strap (Single part)  Cam tie down strap (Two part)  Cam tie down strap (Single part)  Ratchet tie down strap  Winch strap  Bungee cord  Tie down set packed in blister  Tie down set packed in plastic  Use and maintenance 1.In selecting and using tie down straps, consideration shall be given to the required lashing capacity, taking into account the mode of use and the nature of the load to be secured. 2.Check the tension force periodically, especially shortly after starting the journey. 3.Release of the tie down straps: Care should be taken to ensure that the stability of the load is independent of the lashing equipment and that the release of the tie down straps shall not cause the load to fall off the vehicle, thus endangering the personnel. 4.Because of different behaviour and elongation under load conditions, different lashing equipment (e.g. lashing chain and tie down strap) shall not not be used to lash the same load. Consideration shall also be given to ancillary fittings (component) and lashing devices in the load restraint assembly are compatible with the tie down straps. 5.Before attempting to unload a unit of load its tie down straps shall be released so that it can be lifted freely from the load platform. 6.During loading and unloading attention has to be paid to proximity of any low overhead power lines. 7.Tie down straps shall be rejected or returned to our factory or other competent organiztions next to you for repair if they show any signs of damage. The criteria are considered to be signs of damage as follows: Only tie down straps bearing identification labels shall be repaired; If there is any accidental contact with chemical products, a tie down strap shall be removed from service; For tie down straps (to be rejected): tears, cuts, nicks and breaks in load bearing fibres and retaining stitches; deformations resulting from exposure to heat; For end fittings and tensioning devices: deformations, splits, pronounced signs of wear, signs of corrosion. 8. Care should be taken that the tie down straps are not damaged by the sharp edges of the load on which they are used. A visual inspecton before and after each use is recommended. 9. Tie down straps shall never be used when knotted. 10. Damage to labels shall be prevented by keeping them away from sharp edges of the load and, if possible, from the load. |