|

Webbing Slings

Webbing slings

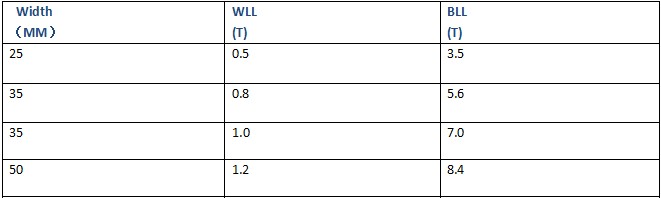

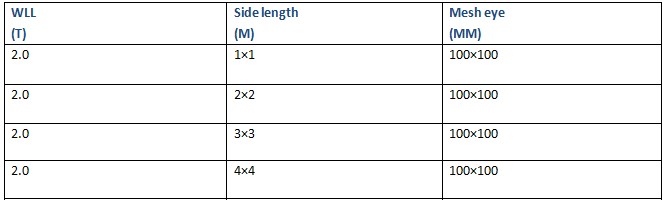

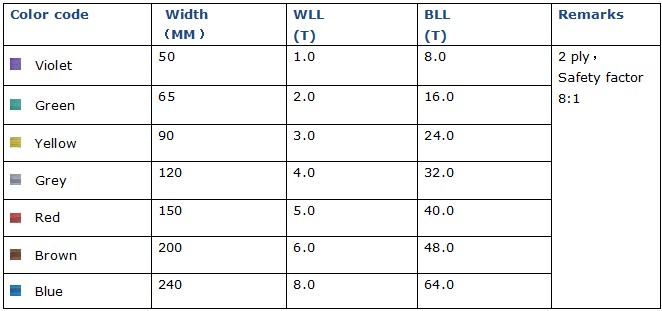

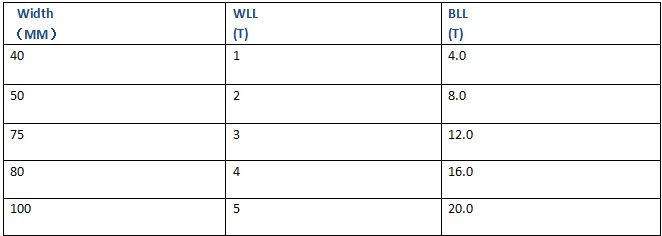

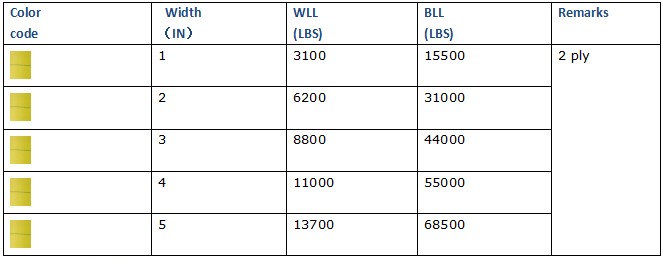

Features: 1. For endless webbing sling, its life span will get longer by changing its loading point in use; 2. It is easy to handle and tight to attach the load surface. The delicate and dyeing surface is kept from damage; 3. High ratio of force to weight, light in weight, and also flexible. It is available that the sling is used without glove or other protective measure; 4. Color code to be fabricated as per international standard verifying WLL of sling; 1 WLL each black line, by which it is easy to identify the WLL of sling; 5. High abrasion resistance, without joint inside, low elongation, at WLL, the elongation not in excess of 3%; 6. It resists twist or knot; 7. Polyester sling keeps from the affect by majority of mine acid, but gets damaged from alkali easily (Nylon sling gets hardly affected by alkali, but it gets damaged from mine acid easily. Polypropylene sling gets hardly affected by acid or alkali, it is suitable for use at the place where there is requirement on resistance to chemicals except solvent ). Not get affected from water, oil or grease entirely; 8. Work and storage temperature: -40℃ to 100℃ (-40℉ to 212℉), same as that of nylon sling, but different from PP sling -40℃ to 80℃ (-40℉to 176℉).  Eye to eye polyester webbing sling Material: 100% polyester Performed standard: EN1492-1 Safety factor: 7:1 Length: 1 to 100M or as required Width: 30 to 300MM WLL: 1 to 10 tons Ply number: 2 Color: As international standard Type: Eye to eye   One way polyester webbing sling Material: 100% polyester Performed standard: EN1492-1 Safety factor: 7:1 Length:0.5 to 10M Ply number: 1 Type: Endless   Polyester webbing lifting mesh  Eye to eye polyester webbing sling Material: 100% polyester Performed standard: AS1353.1 Safety factor: 8:1 Length: 1 to 100M or as required Width: 50 to 300MM WLL: 1 to 10.00 tons Ply number: 2 Color: As international standard Type: Eye to eye   Eye to eye Polypropylene webbing sling Material: 100% polypropylene Performed standard: JB/T8521.1 Safety factor: 4:1 Length: 1 to 100M or as required Width: 40 to 140MM WLL: 1.00 to 10.00 tons Ply number: 4 Color: Original white Type: Eye to eye   Eye to eye Polyester webbing sling Material: 100% polyester Performed standard: ASME B30.9 Safety factor: 5:1 Length: 1 to 100M or as required Width: 1 to 12IN WLL: 3100 to 34100 LBS Ply number: 2 Color: Yellow Type: Eye to eye   Use and maintenance 1.When selecting and specifying slings made from man-made fibers, consideration should be given to the required working load limit, taking into account the mode of use and the nature of the load to be lifted. 2.Webbing slings should not be overloaded: the correct mode factor should be used. Working load limits for some modes have be given on the label. In the case of multi-leg slings the maximum angle to the vertical should not be exceeded. 3.Slings should be protected from edges, friction and abrasion, whether from the load or the lifting appliance. 4.Care should be taken to ensure the safety of personnel during the lift. Persons in the danger area should be warned that the operation is to take place and, if necessary, evacuated from the immediate area. 5.Care should be taken when making the lift to ensure that the load is controlled, e.g. to prevent accidental rotation or collision with other objects. Snatch or shock loading should be avoided as this will increase the forces acting on the sling. A load in the sling or the sling itself should not be dragged over the ground or rough surfaces. 6.The load should be lowered in an equally controlled manner as when lifted. Trapping the sling when lowering the load should be avoided. The load should not rest on the sling, if this could cause damage and pulling the sling from beneath the load when the load is resting on it should not be attempted. 7.On completion of the lifting operation the sling should be returned to proper storage. When not in use, slings should be stored in clean, dry and well ventilated conditions, at ambient temperature and on a rack, away from any heat sources, contact with chemicals, fumes, corrodible surfaces, direct sunlight or other sources of ultra-violet radiation. 8.Prior to placing in storage, slings should be inspected for any damage which may have occurred during use. Damaged slings should never be returned to storage. 9.Where lifting slings have come into contact with acids and/or alkalis, dilution with water or neutralization with suitable media is recommended prior to storage. Depending on the material of the lifting sling and on the chemicals. 10.Slings which have become wet in use, or as the result of cleaning, should be hung up and allowed to dry naturally. 11.Before each use, the sling should be inspected for defects and to ensure that the identification and specification are correct. A sling that is unidentified or defective should never be used, but should be referred to a competent person for examination. 12.During the period of use, frequent checks should be made for defects or damage. If any doubt exists as to the fitness for use, or if any of the required markings have been lost or become illegible, the sling should be removed from service. |